SPS5.2 Controller

- 10 pre-set firing programs

- Top temperature user-adjustable ±100°C

- Large clear illuminated 32 character alphabetic display for user-friendly operation

- Status display shown during firing

- Delayed start facility up to 99hrs. 59mins.

- Control range up to 1310°C

- Attractive compact wall-mounted enclosure sealed to IP65

- R,K,N & S thermocouple types (field selectable)

- Optional internal over-temperature trip module (field installable)

- Thermocouple burn-out detection

- Heater element failure detection

- Intelligent power failure recovery

- Continuous self-checking of internal operation

- Year 2000 compliant

- SPS5.3 has additional ventilation fan control output

Product Description

The SPS5.2 is a 2-stage controller which has been designed in response to demand for an easy to operate pre-set controller suitable for use by Schools & Colleges. It features 10 pre-set programs designed to meet the majority of firing requirements. The top (t2, soak) temperature can be adjusted ±100°C from the pre-set value by the user.

The SPS5.3 adds a ventilation fan control output as required by certain Health & Safety authorities.

Pre-Set Programs

|

Program Number

|

Description

|

Ramp 1 °C/hour

|

t1 °C

|

Ramp 2 °C/hour

|

t2°C

|

Soak Time (mins)

|

| 0 | Lustre | 125 | 375 | 125 | 750 | 0 |

| 1 | On Glaze Enamel | 123 | 400 | 123 | 800 | 0 |

| 2 | Slow Biscuit | 30 | 210 | 113 | 1000 | 0 |

| 3 | Normal Biscuit | 40 | 200 | 114 | 1000 | 10 |

| 4 | High Biscuit | 40 | 200 | 120 | 1160 | 0 |

| 5 | Earthenware Low Temperature Glaze | 100 | 500 | 115 | 960 | 10 |

| 6 | Earthenware Normal Temperature Glaze | 120 | 500 | 120 | 1070 | 0 |

| 7 | Earthenware High Temperature Glaze | 112 | 560 | 112 | 1120 | 10 |

| 8 | Stoneware | 126 | 630 | 126 | 1260 | 10 |

| 9 | Porcelain | 100 | 200 | 210 | 1280 | 10 |

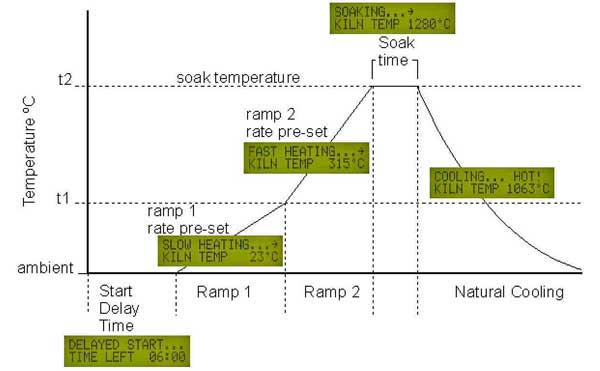

Firing Sequence

(Typical displays for Porcelain firing shown)

Setting

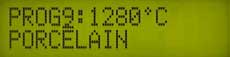

Pressing the SET key causes the display to prompt the user for a program as shown. The required program is selected with the up-arrow key.

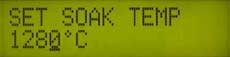

Pressing the SET key again enables adjustment of the soak temperature by up to ±100°C.

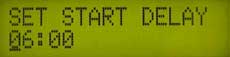

A 3rd press of the SET key causes the display to prompt for the start delay - this can be set in the range 00:00 (immediate start) to 99hrs:59mins.

A final press of the SET key returns the instrument to READY mode

Running

The RUN/HALT key is used to run the firing sequence. This key can also be used to halt the firing at any time. The status of the firing is shown on the display

.Additional Displays

During firing additional status information is displayed. This information is sequenced on the top line of the display once per minute or when the right-arrow key is pressed. It acts as a user confidence check of what program is running & how far the program has progressed. Some typical displays are shown below:-

| Slow Heating... | Fast Heating... | Soaking... |

Specification

Electrical

- Power Supply

Power supply voltage range: 216.2 -253V

Frequency: 50Hz

Controller Power: 3VA

Switched outputs: 75VA max

Fuse: 1A anti-surge

Kiln Control Relay

Contact type: SPST NO

Contact configuration: Switched Live 230VAC @ 0.3A max

Fan Control Relay (SPS5.3 only)

Contact type: SPST NO

Contact configuration: Switched Live 230VAC @ 0.3A max.

Thermocouple

Type (user selectable): K,N,R or S

Connectors

2-part connectors - wire size: 1.5mm² max.

- t2 setting

Trim range: ±100°C

Resolution: 1°C

Start Delay

Range: 00:00 to 99hrs : 59mins

Control Accuracy

Control type: P.I.D.

Accuracy: ±0.25% FSD + 1 digit

Operating temperature range: 0 to +40°C

Storage temperature range: -10°C to +55°C

Enclosure sealing: IP65

Enclosure material: ABS or Polycarbonate

Enclosure colour: Light grey RAL 7035

Enclosure size (h x w x d): 160mm x 120mm x 94mm

This instrument is designed for use mainly in Domestic & Light Industrial environments where electro-magnetic interference may cause a loss of accuracy of the displayed reading of up to 3°C. Specified accuracy will be restored when the interference is removed.

The design of this instrument has been assessed and tested assuming maximum connecting lead lengths of 3.0 metres.